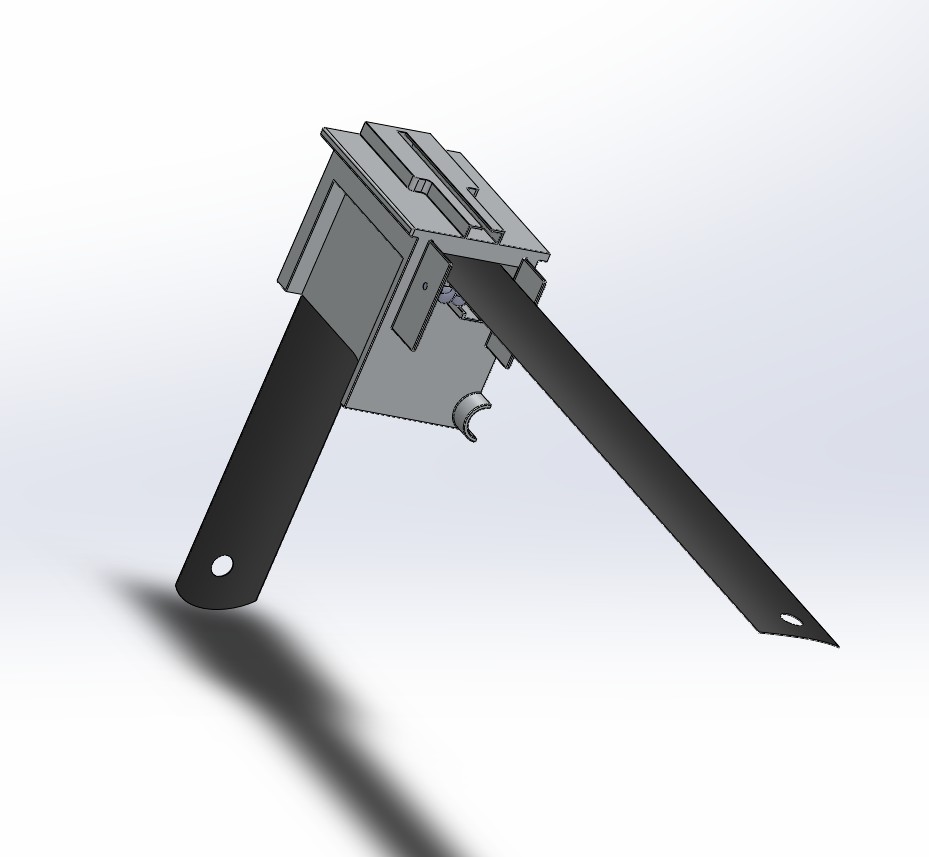

Coated steel strip(sheet)(insect screen use)

STEEL STRIP PROCESSING

(Insect screen or mesh use)

This product is designed for insect screen or insect mesh use. We have over 30 years of stamping experience. Not only could we accurately control the length and hole positional exacting tolerances and minimal clearances of carbon steel sheets, but could offer customized production according to your specific requirements for length and hole-position. Our seasoned experience and professional techniques ensure each product that has a clean and aesthetically pleasing cutting surface; we also offer laser engraving service, allowing you to engrave the desired text or patterns and create unique products that are exclusively yours; finally, we apply special coating surface treatment to enhance the finished products with excellent bendability and powerful corrosion resistance capability. The above techniques and processes not only ensure the highest quality assurance for each product but save you from the troubles of material damage and defects during subsequent processing, which could result in wastage of raw material.

.jpg)