Heat Treatment 鋼(帶)捲熱處理加工 Hardened & Tempered Steel Strip

Heat treatment is the process of heating and cooling of metals to change the steel's physical and mechanical properties without changing the original shape and size. The most common heat treatment material is carbon steel.

熱處理是加熱及冷卻金屬不改變原來的形狀和大小的情況下, 更改金屬的物理力學性能的過程. 常見的熱處理金屬為碳鋼.

Heat treatment is often associated with increasing the strength of the steel, but it can also be used to alter certain manufacture ability objectives such as improve machine ability, form ability, restore ductility etc. Thus heat treatment is a very useful process to helps other manufacturing processes and also improve product performance by increasing strength or provides other desirable characteristics.

熱處理往往是用於提高鋼的強度,但它也可以用來改變某些因應製造必要的目標, 比如改善加工性能, 成形, 還原延性等。因此熱處理是非常有用的過程來幫助理其他製造過程和也增加產品的性能或提供其他想要達成的產品特徵。

熱處理特別適合高碳鋼, 因為碳鋼好回應熱處理及商業用途的鋼超過任何其他金屬材料.

京琳有超過20年的熱處理加工技術, 因應客戶的需求可提供多種熱處理加工. 我們可以提供材料及熱處理加工的一次性服務. 我們也接受客戶提供材料只做熱處理加工服務. 熱處理後亦可依客戶需求做表面加工處理.

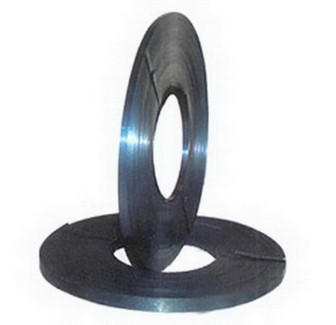

High carbon steels are particularly suitable for heat treatment, since carbon steel respond well to heat treatment and the commercial use of steels exceeds that of any other material. After heat treatment, the steel surface can be grided in different surface color. Please refer to the surface finish web page for more information. With over 20 years experiences of heat treatment skills, NKS Steel is able to provide many different types of heat treatment processes. Each heat treatment individual process provides different desirable characteristics to the product. For a quote and advice on all your hardening and heat treatment needs, contact us now. After heat treatment process, steel strips can be re-rolled into ribbon-wound coils (pancake) or oscillated-wound coils (oscillation coils). For more detail please refer to the Main Steel / Steel Strip.